Manufacturing is no longer the path to opportunity it once was

Automation, declining unions, and the trade shocks have created barriers to manufacturing workers, particularly those without college degrees

Interesting on the web:

🎉 We’ve built a new Opportunity Mapping tool for policymakers to understand the biggest issue in their county and which region is addressing that issue best - link

👾 New ChatGPT tool allows you to query census data much more easily with searches like “cities with a population over 100,000 and lowest crime" - link

😷 I know we’ve all had our fair share of COVID-19 maps/visualizations, but this 3-year time series is pretty good - link

U.S. manufacturing has had the biggest decline in employment of any sector in the last 40 years. Since the year 2000, the U.S. has lost over a quarter of its manufacturing jobs.

The decline in manufacturing has had a negative impact on wages, particularly for non-college educated Americans. In 1960, 37% of non-college educated men worked in manufacturing, but that share declined to just 15% by 2015. Instead, jobs that do not require a college degree have increasingly shifted to the service industry, where the pay is lower, hours are less certain, and collective bargaining is much weaker.

Working in manufacturing used to be a great way to break into the middle-class, particularly for non-college educated Americans. In 1990, manufacturing workers were earning $10.78/hr or 6% more than their peers in non-management roles ($10.20/hr). But by 2018, manufacturing workers were earning approximately 5% less ($21.54) than peers ($22.71).

These trends have made it harder for certain communities to achieve the American Dream. What was once a reliable job either no longer exists, or comes with far lower wages. Given the rising cost of higher education, we need to ensure that we still have reliable paths to prosperity for workers across the country without college degrees.

📍 Rochester, NY has had one of the highest losses in manufacturing jobs over the last 30 years. Nearly 1 in 2 manufacturing workers there lost their jobs. As companies like Kodak, Xerox, and Bausch and Lomb lost market share to Fuji and others, 60,000 manufacturing jobs in Rochester disappeared.

The shifting tide against US manufacturing is the product of 3 main factors, though economists and policymakers disagree on the impact of each - trade shocks, automation, and de-unionization.

Ronald Wilson, like his father, worked at the Gulf States Steel mill in Gadsden, Alabama for years. Ronald started working there at age 18, and his father worked there until the day he died. But after 36 years there, Ronald was laid off when the plant closed. He took an auto-body class to try to develop more skills, but instead drove a truck for some time hauling waste, until a heart attack forced an early retirement. 1,700 people were laid off when the plant closed in a region where 1 in 5 people work in manufacturing. After the facility was sold, parts of it were shipped overseas and now there is nothing there but the shell of a building.

Trade shocks have hurt non-college educated manufacturing workers

In the early 1990s, dramatic economic reforms in China led by Deng Xiaoping lifted protectionist policies, price controls, and certain regulations, making China much more competitive. In 2001, China joined the World Trade Organization (WTO), changing how its flow of manufacturing imports and exports move across the globe. Accordingly, the US and the rest of the world began importing far more from China. This led to a decline in U.S. manufacturing jobs, but this was not offset by job gains in non-manufacturing jobs. As a result, Americans lost their jobs. Those who didn’t had to endure lower wages as they competed globally.

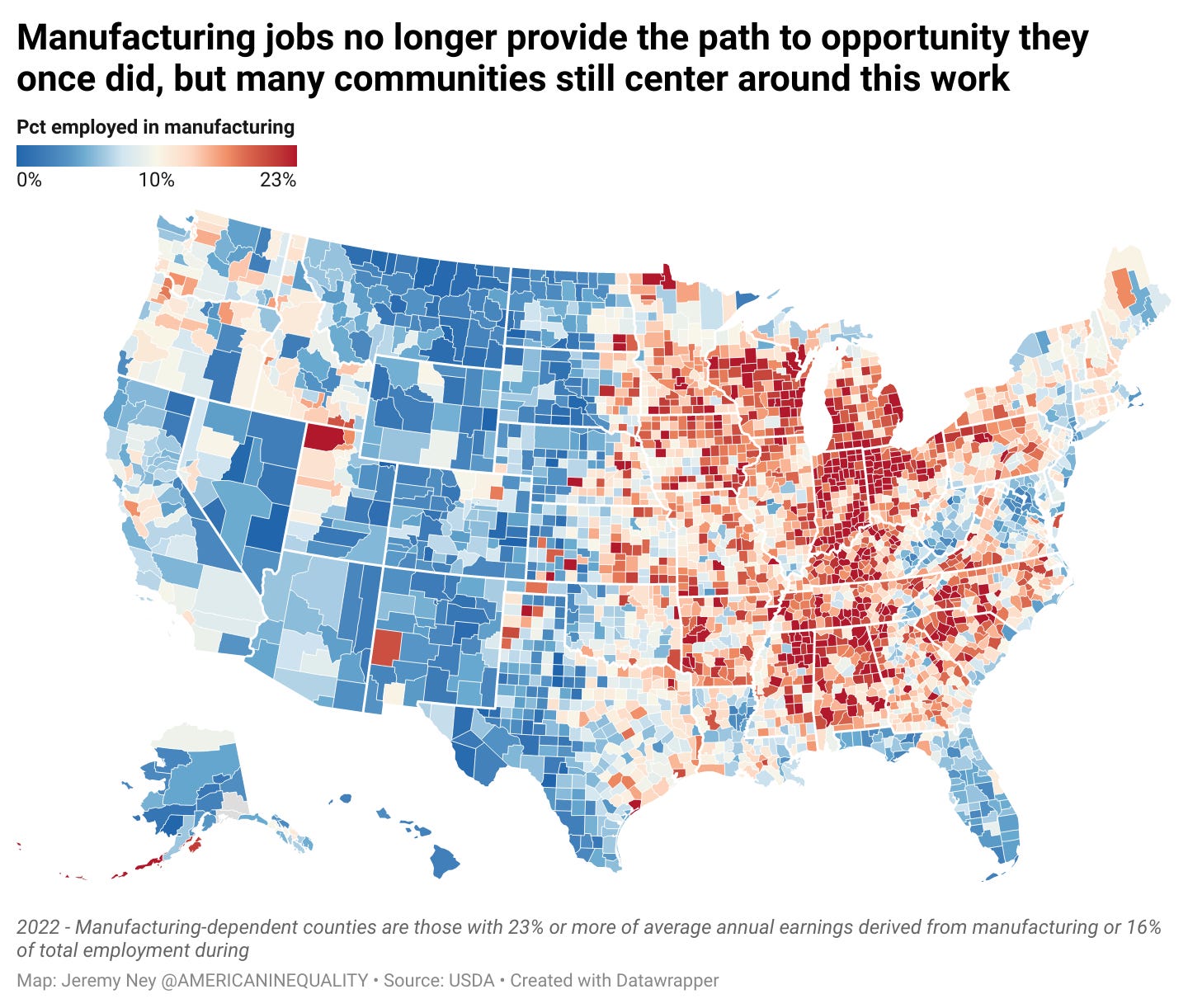

In half the US counties classified as manufacturing dependent (i.e. manufacturing accounts for 23% of the workforce or a large share of the region’s economy), median incomes have fallen by more than 10% from 2000 to 2016. The declines were not nearly as steep or severe for non-manufacturing dependent regions.

Automation displaced workers

“Digital automation since the 1980s has added to labor market inequality, as many production workers saw their jobs disappear or their wages decline.” The Brookings Institute explains that while automation can often produce more jobs for the economy, for workers whose jobs can be substitutes for automation, those workers’ jobs are being automated away.

Researchers from MIT found that for every robot added per 1,000 workers, wages decline by 0.42% and the employment-to-population ratio goes down by 0.2%. However, these declines may double in manufacturing regions. This was not just a US phenomenon - the researchers found that the same held true for automation in France.

By some estimates, automation contributed to 400,000 manufacturing workers losing their jobs between 1990 and 2007.

The COVID-19 pandemic likely accelerated this job loss, as companies had to figure out how to make due with fewer in-person workers. Some estimates say that between 2021 and 2025, robots may replace 2 million manufacturing jobs.

Unions were a safe haven for manufacturing

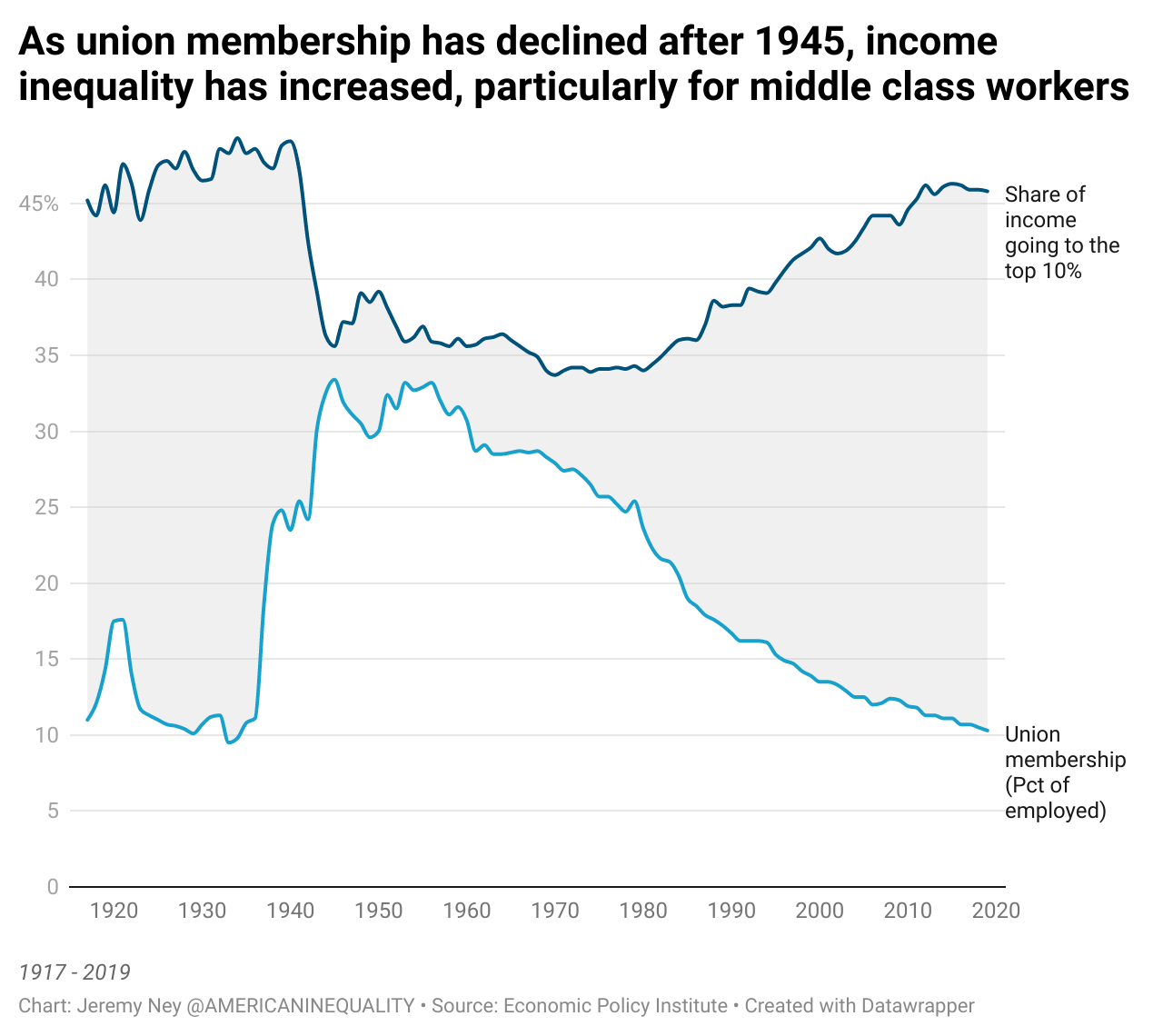

In the 1970s, nearly 1 in 3 workers were part of a union. Today, the number has dropped to 1 in 10. The Federal Reserve found that this decline in union membership explains about 70% of the decline in wages that manufacturing workers have seen since 1990.

More broadly, the decline in unionization has led to a broad increase in inequality across employment sectors. Unions had proven to shrink the Black-White employment gap and were able to increase wages for non-college educated workers. Workers covered by a union contract earn 13.2% percent more in higher wages than do peers with similar education, occupation, and experience. With the decline of unions, the share of incomes going to the top 10% has increased and the Black-White wage gap has grown as well.

This shift has been particularly detrimental for manufacturing workers, who tend to be more unionized than their peers in other lines of work.

The Path Forward

As manufacturing jobs are disappearing for non-college educated Americans, paths to prosperity still exist. We may not be able to reverse trade shocks or automation, but we can support workers. Policymakers can reverse some of the trends that have negatively impacted American manufacturing jobs, but new structural changes can also help open new doors.

🚀 Grow union membership - The U.S. Department of Labor explains that “Labor unions improve wages and working conditions… reduce wage gaps for women workers and workers of color. And union members have better job safety protections and better paid leave than non-union workers.” In 1985, there were almost 5 million union members in manufacturing, compared to 1.18 million in 2021. 71% of Americans approve of unions in a survey taken in 2022. “Wage Boards” offer a solution here. Wage Boards bring together workers, businesses, and government, to recommend wage standards, training, paid time off, and other workplace standards. Getting rid of certain right-to-work laws (which can undermine unions by allowing workers to opt-out of unions) can also grow union membership, as these laws were found to decrease union membership by 4% and decrease wages by 1%.

👷♂️ Retrain manufacturing workers looking for new roles - The World Economic Forum estimates that by 2025, 50% of all employees will need reskilling due to technological change. In particular, as the U.S. finds itself struggling to compete with East Asian countries in high-tech manufacturing, reskilling our workers can help ensure their ability to adapt to changing market conditions. This also helps move the U.S. in line with market forces, rather than taking trade-restrictive policies that may end up driving prices higher.

🚧 Boost demand through infrastructure investments - America needs new bridges, airports, ports, water pipelines, and highways. A thriving manufacturing sector can support this growth. It will be hard to combat the cheap labor of China and other Asian countries that have moved a lot of manufacturing jobs overseas, but infrastructure is hard to outsource. Instead, the U.S. can focus on large scale projects that require skills and trades that manufacturing workers have. This approach helped the U.S. add 696,000 manufacturing jobs in Biden’s first 20 months in office.

🧑🎓 Stop requiring college degrees for jobs that don’t need them - 70 million American workers never graduated from college. While the Democratic party has spent decades prioritizing college admission, it’s time to recognize that not all jobs need higher degrees. Studies have found that 60% of employers reject workers because they don’t have a B.A. from college, even though they have the necessary skills and experience to do the job. Programs like Opportunity@Work help these workers land jobs and help employers see that they don’t need to request college degrees. This has helped open up an additional 1.4 million jobs by tearing the paper ceiling.

In the period after World War II, manufacturing workers were in a unique position to make wage gains. Strong unions had public support and with Japanese and European industrial centers destroyed, US workers who had spent time on production lines were able to make tremendous gains. Wages also rose for those workers who were in high demand.

In the 1950s, consumers wanted new homes, more cars, and better appliances. Demand for manufacturing jobs was further bolstered by huge investments in new highways, roads, and suburban homes.

However, the 1960s brought on big changes that would turn the tide by the 1980s.

Let’s learn from the historical successes of the 1940s - 1960s that allowed manufacturing workers to make wage gains, to thrive in secure job environments, and to build the products and infrastructure that Americans so dearly needed. American manufacturing can have a resurgence (and the Infrastructure Bill and CHIPS Act will help us get there), but we also need to ensure we’re focusing on regions that stand the most to benefit from resurgent American manufacturing.

Great analysis! And I find the 2018 inflection point very interesting. I've studied the trade shock and the impact on manufacturing a bit and noted a divergence between high vs low skilled manufacturing work. Since the US is actually producing more manufacturing output than it has in the past, a lot of is driven by high skill manufacturing. Two additional points - I'd make: unfortunately, re-training problems have been shown to have limited effectiveness - actually to such a degree that it would be better to just give the money to the displaced manufacturing worker rather than funding them. Second, the issue with long run manufacturing employment is that people entering the labor force have already adjusted their expectations about the economy going forward. One of the biggest issues of the trade shock generated by China joining the WTO was that people who were in manufacturing were all of a sudden put at a disadvantage with no possible alternative (re-training is costly). So their lifetime incomes went down in both nominal and real terms. New people entering the labor market, see that manufacturing (especially the low skill manufacturing) does not pay as much, so they choose other sectors - mainly the service sector. This creates a hollowing out by age - few if any young people enter manufacturing (an example of this was the US textile industry under the Multi-Fibre Agreement - people did not train become textile workers, while the older textile workers just stayed in it until the industry died out). Convincing new people to become manufacturing workers is difficult because of commitment issues - does anyone believe manufacturing is here to stay for 40 years when they enter the labor force?

The core problem with manufacturing in America is that the infrastructure isn’t here the same way it is in other countries. For example, a lot of machinery is made overseas and the people familiar with those machines are overseas too. This makes it incredibly difficult to manufacture here. A other example, finding skilled labor is really really hard. Can barely find people with knowledge of lean manufacturing in states like Utah and California. In Mexico, it’s very easy.

I am not sure the solutions you propose will really do much. The real problem is that American made products are very difficult to produce in a cost effective way that meets consumer expectations. Maybe this will change as robotics become widespread.